End-To-End Proactive Pipeline Monitoring Solutions

APS Inc. delivers fiber-optic sensing solutions with predictive analytics that transform passive pipeline monitoring into intelligent, proactive integrity assurance. We prevent failures before they occur while providing actionable insights through complete end-to-end solutions that set new industry standards.

Why Distributed Fiber Optic Sensing (DFOS)?

Distributed Fiber Optic Sensing (DFOS) represents a revolutionary advancement in pipeline monitoring technology. Unlike conventional strain gauges and accelerometers, DFOS provides continuous, long-range monitoring with superior accuracy and reliability.

Our DFOS solution offers maintenance-free operation, complete EMI immunity, and exceptional temperature tolerance. With a lifespan exceeding 30 years and intrinsically safe passive operation, it delivers unmatched value for critical infrastructure monitoring.

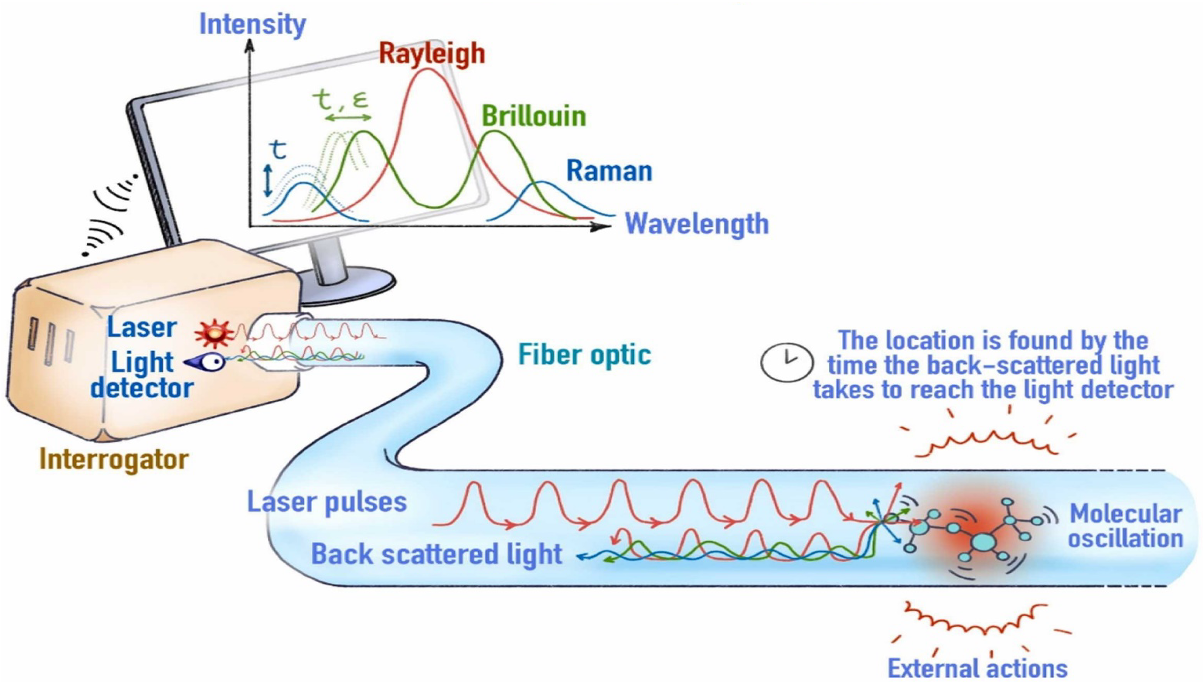

How DFOS works?

Our DFOS technology utilizes advanced laser interrogation systems to detect minute changes in optical fiber properties. The system sends laser pulses through standard telecommunications fiber and analyzes the backscattered light to determine strain, temperature, and acoustic signatures along the entire fiber length.

Our solution

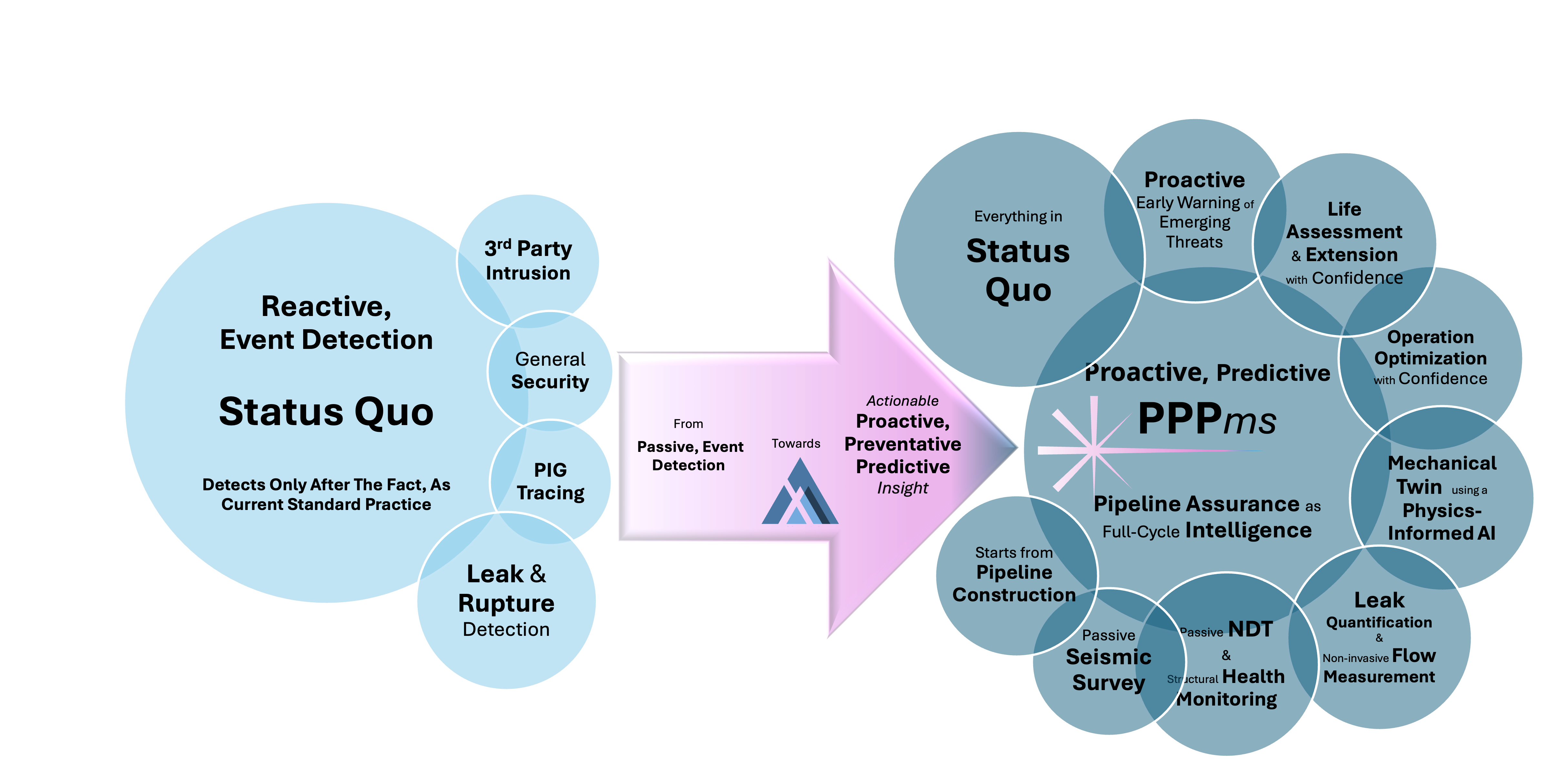

Our comprehensive DFOS solution transforms traditional pipeline monitoring from reactive event detection to proactive, predictive intelligence. By leveraging advanced fiber optic sensing technology, we enable continuous monitoring and early warning systems that prevent costly failures and optimize operational efficiency.

The transition from Status Quo to PPPms (Proactive, Predictive Pipeline Management system) represents a paradigm shift in infrastructure management. Our solution provides full-cycle intelligence from pipeline construction through operational optimization, delivering unprecedented visibility into asset health and performance.

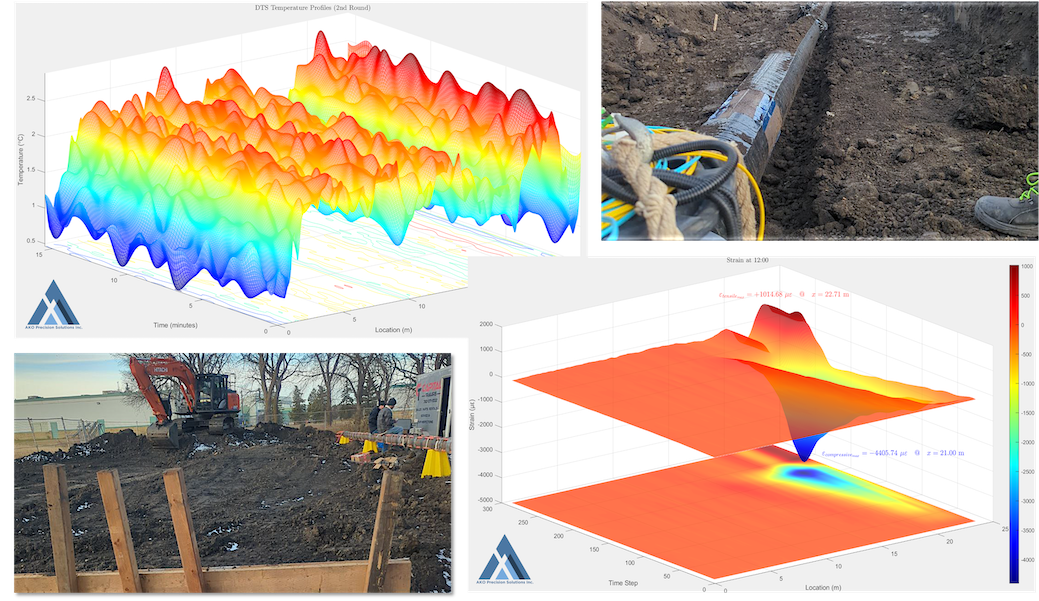

Our results

Our DFOS technology has delivered exceptional results across numerous real-world applications, providing continuous temperature and strain monitoring with unprecedented accuracy. The comprehensive data visualization capabilities enable operators to make informed decisions based on real-time infrastructure health insights.

Field deployments demonstrate the system's ability to detect micro-strain variations, temperature anomalies, and structural changes across kilometers of pipeline infrastructure. The 3D visualization and heat mapping capabilities provide intuitive understanding of complex data patterns for enhanced operational intelligence.